Maintenance, servicing and repair work

We offer support for problems with your machines and the overhaul of engines. Our specialists will gladly assist you in the maintenance and possible repair work or in the manufacture of new components.

Our qualified technical staff carries out maintenance, repair and repair work on machines, units and systems in ship operation or industrial plants.

We offer maintenance and repair work on site or at our factory. Your installed equipment will be serviced and maintained by our qualified mechanics upon request. In addition, we are happy to prepare concepts for modernizing your systems.

New construction, maintenance or repair of the following plants

Compressors

For optimum compressed

air generation.

Centrifugal Pumps

In every conceivable

size and capacity.

Generators

From 1 to 2,500 kVA in hood or

container construction.

Cooler & heat exchanger

Radiator and heat exchanger

made of aluminum.

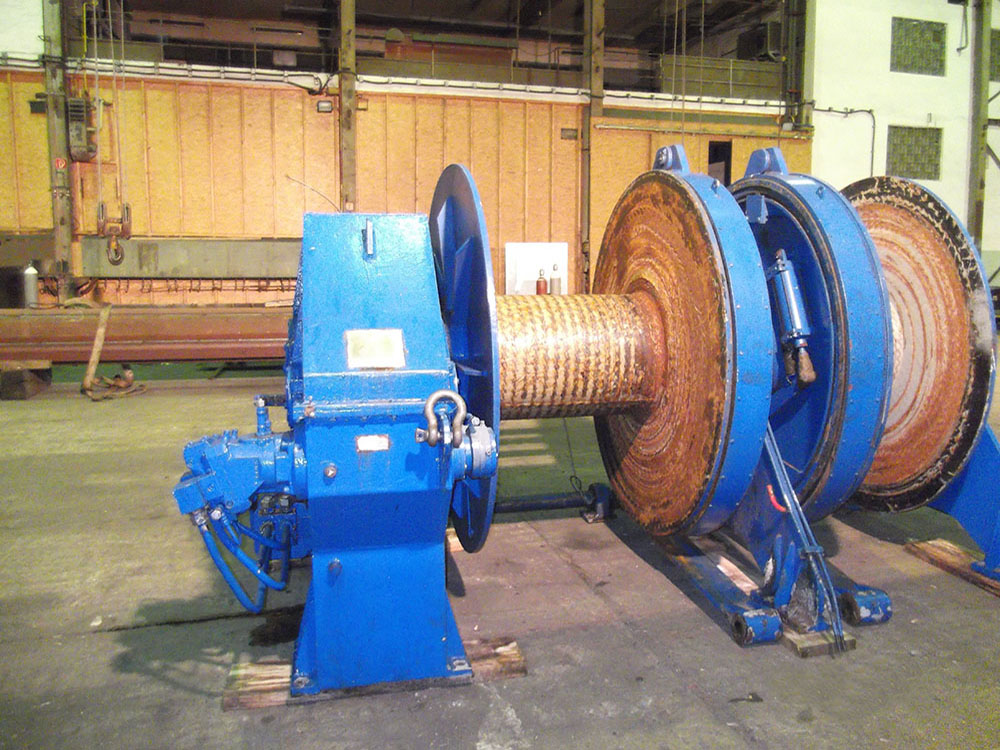

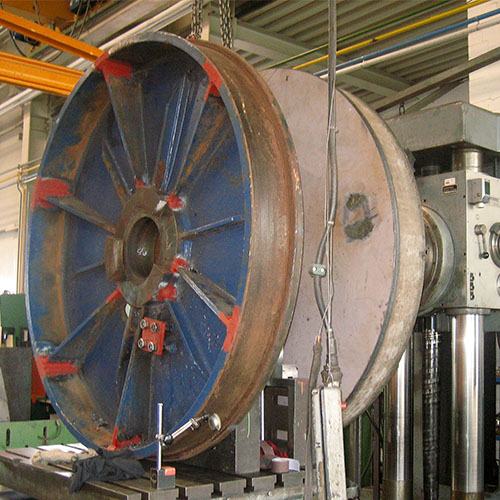

Winden

On the expansion and repair of large components such. B. Winches are specialized by our staff. Through our large halls and our modern equipment park, we can machine components up to a total weight of 60 tons.

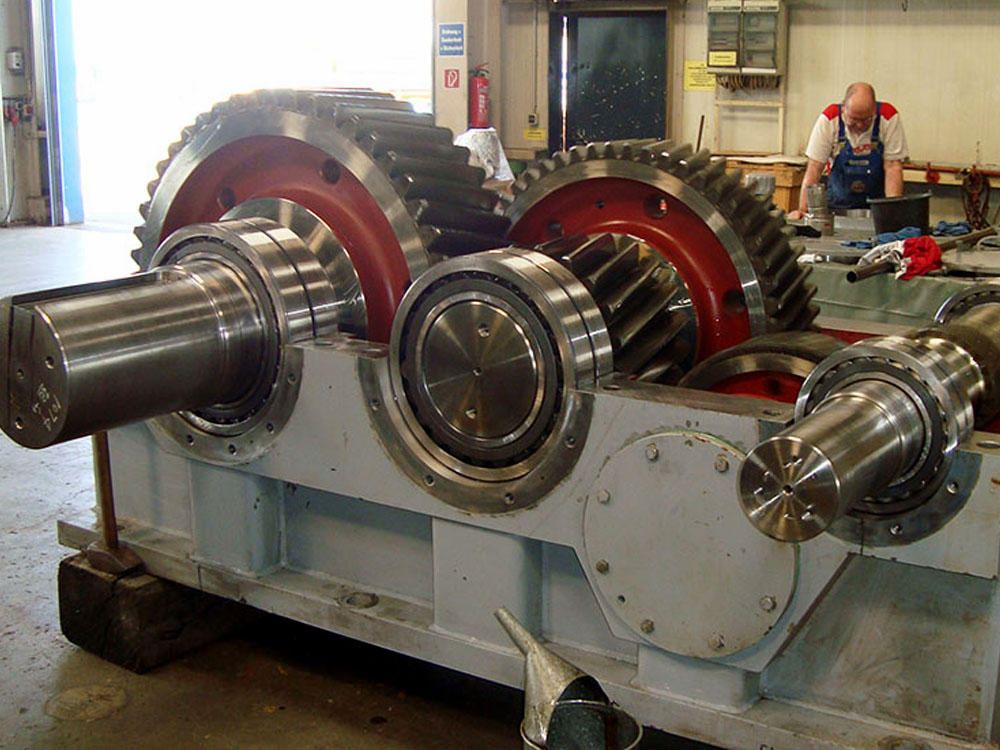

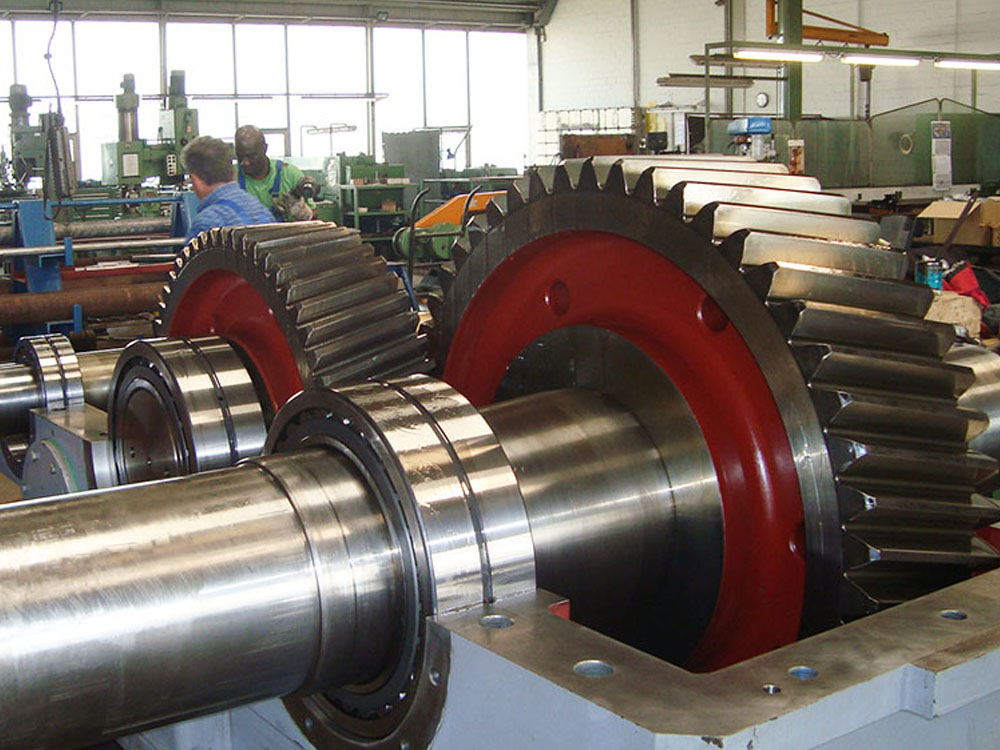

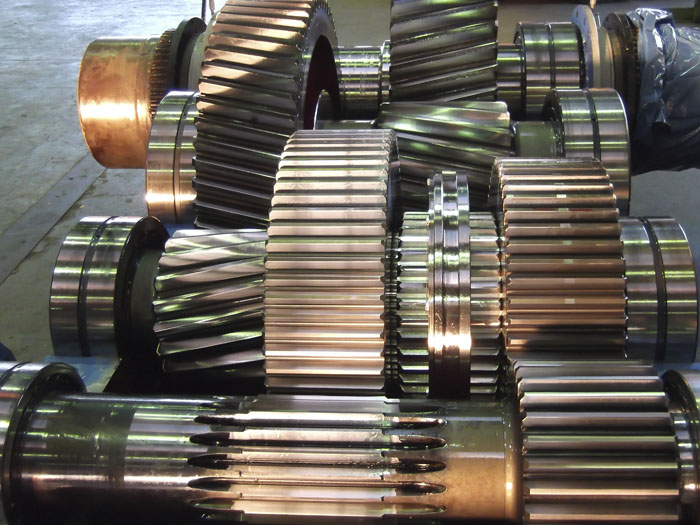

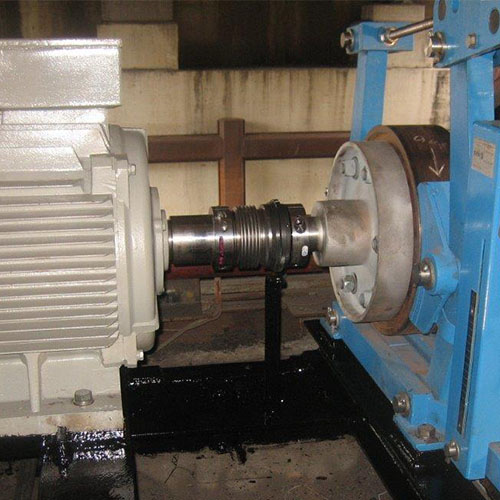

Drive Systems

Benefit from our many years of experience in dealing with motors for drive and conveyor technology. For new construction or renovation, our trained staff will undertake the installation, maintenance or repair with the necessary expertise.

Bow thruster

We carry out repairs, installation and removal as well as service work on bow thrusters in our mechanical engineering workshop or directly on site on the ship. This also includes service work on the electric or hydraulic drives.

Hydraulic cylinder

Overhaul, maintenance and repair of hydraulic cylinders of all sizes. This also includes disassembly and reassembly of the cylinders on the ship including transport and test runs.

Fire pumps

Fire pumps and fire monitors are professionally maintained and repaired. Thanks to our electrical engineering, pumps can be repaired not only on the pressure side but also on the drive side.

Maintenance of machines for more safety

Whether small or large, old or new, regular maintenance by the specialist increases the longevity and operational safety of the machine. Regular maintenance could save costs and improve safety for your employees! This includes a thorough cleaning of the technical equipment, the lubrication, greasing of components, the tightening of z. B. bearings, timing belts and the replacement of worn parts and seals.

Contact us now – we are happy to advise you!